Objectives:

The project aims to master the incremental sheet metal forming technology integrated with a heating combined ultrasonic vibration system. Specifically, the project will focus on designing and fabricating an incremental forming fixture equipped with a heating system and an ultrasonic vibration device. Moreover, the project will enhance simulation accuracy for the forming process by developing forming limit diagrams (FLDs) to predict material failure, subsequently validated through experiments. The anticipated outcomes include increased productivity and quality in forming titanium alloy components, alongside significant reductions in production time, costs, and material waste. This advanced technology is applied in manufacturing specialized medical implants, including bone plates, cranial repair devices, prosthetic limbs, knee joints, facial reconstruction implants, and palatal prostheses

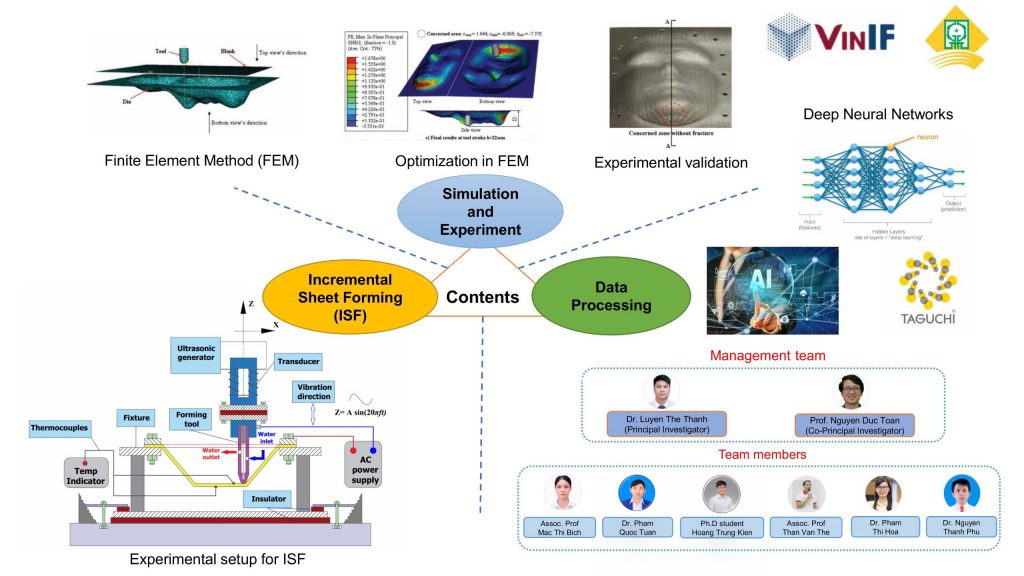

Activities:

– Design and fabricate an experimental system for incremental forming, integrating a heating system and an ultrasonic vibration device.

– Conduct a practical survey of biomedical components such as cranial plates, knee joints, and denture bases to propose rapid prototyping solutions for human body replacement products.

– Study material modeling and theoretical foundations of the forming limit curve at fracture (FLCF) of sheet materials used in biomedical applications at room and elevated temperatures.

– Investigate the effects of FLCF and technological parameters on the incremental forming process with integrated heating and ultrasonic vibration assistance.

– Study the optimization of technological parameters to improve the output criteria of the incremental forming process with integrated heating and ultrasonic vibration assistance.

Impact:

The core of this project involves utilizing incremental forming technology to manufacture biomedical components made from materials with high hardness and strength, such as titanium alloys. This research requires the development of an incremental forming system integrated with a heating system and an ultrasonic vibration device. The heating system facilitates the process by making the material easier to form, while the ultrasonic vibration system contributes to improving machining accuracy and enhancing product quality.

The results of this research will be published in prestigious scientific journals indexed by ISI (Q1) and presented at reputable international scientific conferences. These findings will serve as a valuable resource for faculty members and students at universities and research institutes. Additionally, the project aims to register a patent or develop a practical solution for the research product.

The project will enhance the research capabilities and mastery of incremental forming technology for domestic faculty members and young scientists. At the same time, it will address the challenges of forming high-hardness materials used in biomedical applications, enabling rapid prototyping of replacement components in the biomedical field. The findings of this research have the potential for commercialization, facilitating the transfer of technology to the biomedical sector. Additionally, it aims to enhance the efficiency of forming processes for components like cranial plates, knee joints, and denture bases, while reducing manufacturing costs for these parts.